- Hetronic Programming Manual Software

- Hetronic Programming Manual Pdf

- Hetronic Programming Manual Software

- Hetronic Programming Manual Instruction

- Hetronic Programming Manual Programming

- Hetronic Programming Manual Guide

Hetronic disclaims liability for any claims or damages, whether warranty, property THE MANUAL damage, personal injury or death arising out of the use Before operation of the crane/machine and remote of unauthorized replacement parts. Control system, read your manuals carefully and completely. This manual describes the basic functionality of the HC500 Heater Controller using a CPU-unit (CU) with firmware v1.15 or newer. R The HC500 is a multi channel power controller to setup the heat level of resistors (infrared heaters, infrared lamps, cartridge heaters.) while switching full sinusoid waves of the ac power voltage.

Model eC3200

TelesCopiC Crane

owners’ Manual

installation • assembly drawings • parts

EC3200

42818

Subject to Change without Notification. © 2012 Stellar Industries, Inc.

Stellar Industries, Inc.

190 State Street

PO Box 169

Garner, IA 50438 800-321-3741 Fax: 641-923-2811

www.stellarindustries.com

EC3200 Manual Revisions

Date of Revision | Section Revised | Description of Revision |

Table of Contents i

Table of Contents

Chapter 1 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Capacity Chart - Decal PN 42817. . . . . . . . . . . . . . . . . . 2

Chapter 2 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flatbed Body Reinforcement . . . . . . . . . . . . . . . . . . . . . . 5

EC3200 Mounting Detail . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EC3200 Installation Drawing . . . . . . . . . . . . . . . . . . . . . . . 6

Hydraulic Kit - PN 42799. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Control Kit - PN 42804 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EC3200 Wiring Diagram (Two Battery) . . . . . . . . . . . . . . 9

EC3200 Wiring Diagram (One Battery) . . . . . . . . . . . . . 10

Valve Bank Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Stability Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Stability Capacity Chart . . . . . . . . . . . . . . . . . . . . . . . . . 13

Decal Kit Placement - PN 42816 . . . . . . . . . . . . . . . . . . 14

Chapter 3 - Assembly Drawings. . . . . . . . . . . . . . . . . . . . . 15

Base Assembly - PN 42525 . . . . . . . . . . . . . . . . . . . . . . . 15

Base Assembly (Narrow Version) - PN 44613. . . . . . . . . 16

Mast Assembly - PN 42787 . . . . . . . . . . . . . . . . . . . . . . . 17

Main Boom Assembly - PN 42512. . . . . . . . . . . . . . . . . . 18

Extension Boom Assembly - PN 42520 . . . . . . . . . . . . . . 19

Cable & Hook Assembly - PN 42781 . . . . . . . . . . . . . . . 20

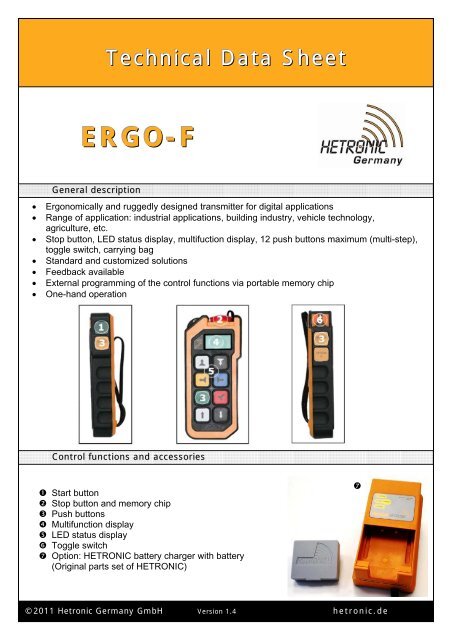

Radio Transmitter Assembly . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 4 - Replacement Parts . . . . . . . . . . . . . . . . . . . . . 23

Find a Dealer Near You:

http://www.stellarindustries.com/pages/dist/distsearch.htm

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at

800-321-3741

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST

Or email at the following addresses:

Technical Questions, and Information | service@stellarindustries.com |

Order Parts | parts@stellarindustries.com |

Warranty Information | warranty@stellarindustries.com |

ii EC3200 Owner’s Manual

This page intentionally left blank.

Specifications 1

Chapter 1 - Specifications

Model EC3200 Crane | |

SPECIFICATION SHEET | |

Crane Rating: | 11,500 ft-lb (1.59 TM) |

Standard Boom Length: | 7’ (2.13 m) from CL of Crane |

Boom Extension: | 1st stage: Hydraulic 48' (121.9 cm) |

2nd stage: Manual 48' (121.9 cm) | |

Maximum Horizontal Reach: | 15’ (4.57 m) from CL of Crane |

Maximum Vertical Lift: | 16’ 2” (4.93 m) |

(from crane base) | |

Boom Elevation: | -5 to +80 degrees |

Stowed Height: | 24” (61.0 cm) |

(crane only) | |

Mounting Space Required: | 18” x 15” (45.7 x 38.1 cm) |

Approximate Crane Weight: | 730 lbs (331 kg) |

Controls: | Radio control standard for all functions. |

Winch Specifications | |

Rope Length: | 65 ft (19.8 m) |

Rope Diameter: | 7/32' (.56 cm) |

Line pull speed: | 15 ft/min (4.6 m/min) |

Max. single part line: | 1600 lbs (725 kg) |

Max. double part line: | 3200 lbs (1450 kg) |

Rotation: | 410 degree power |

(worm gear) | |

Lifting Capacities: | 1625 lbs @ 7’ (737 kg @ 2.1 m) |

905 lbs @ 11’ (410 kg @ 3.35 m) | |

640 lbs @ 15’ (290 kg @ 4.6 m) | |

Power Supply Required: | 12 volt power unit |

(2.0 gpm @ 2600 psi) | |

(7.57 lpm @ 179 bar) |

2EC3200 Owner’s Manual

Capacity Chart - Decal PN 42817

*3200 lbs | *3025 lbs | Reach in Feet/Meters | ||||

Capacity in Pounds/Kilograms | 16’2” | |||||

1450 kg | 1372 kg | |||||

4.92 M | ||||||

*1550 lbs | 15’ | |||||

703 KG | ||||||

4.57 M | ||||||

3200 lbs | 3200 lbs | 1090 lbs | ||||

1450 kg | 1450 kg | 495 kg | 12’ | |||

2145 lbs | ||||||

973 kg | 3.66 M | |||||

1490 lbs | 890 lbs | |||||

3200 lbs | 404 kg | |||||

675 kg | ||||||

3200 lbs | 9’ | |||||

1450 kg | ||||||

1450 kg | 3200 lbs | 2.74 M | ||||

80º | ||||||

75º | 1450 kg | 1215 lbs | ||||

60º | 2415 lbs | |||||

550 kg | ||||||

45º | 1095 kg | 780 lbs | ||||

6’ | ||||||

1900 lbs | 353 kg | |||||

1.83 M | ||||||

30º | 862 kg | 1085 lbs | ||||

1710 lbs | 492 kg | |||||

775 kg | 3’ | |||||

15º | ||||||

.914 M | ||||||

1565 lbs | 905 lbs | 640 lbs | ||||

290 kg | ||||||

83.69 | 710 kg | 410 kg | ||||

0’ | ||||||

0’ | 3’ | 6’ | 7’ | 11’ | 15’ | |

.914 M | 1.83 M | 2.13 M | 3.35 M | 4.57 M | ||

Weight of load handling devices are part of the load lifted and must be deducted from the capacity.

Maximum 1 - part line capacity is 1600lbs (725kg). For greater loads,

Hetronic Programming Manual Software

use 2 - part line.

®EC3200

Installation 3

Chapter 2 - Installation

Notice: Read this Page Before Installation of the Crane

General Installation | Installation Notice |

This chapter is designed to serve as a | According to Federal Law (49 cfr part 571), |

general guide for the installation of a Stellar | each final-stage manufacturer shall |

EC3200 Crane on a Stellar Service Body. | complete the vehicle in such a manner that |

Each installation is considered unique so | it conforms to the standards in effect on the |

certain portions of this chapter may or may | date of manufacture of the incomplete |

not apply to your direct application. If a | vehicle, the date of final completion, or a |

question should arise during the installation | date between those two dates. This |

process, please contact Stellar Customer | requirement shall, however, be superseded |

Service at (800) 321 3741. | by any conflicting provisions of a standard |

that applies by its terms to vehicles | |

This crane is designed for use with a Stellar | manufactured in two or more stages. |

Service Body installed on a vehicle that | |

meets the minimum chassis requirements of | Therefore, the installer of Stellar cranes and |

the crane. It is the installer’s responsibility to | bodies is considered one of the |

assure that the crane is mounted on a | manufacturers of the vehicle. As such a |

platform that will support the maximum | manufacturer, the installer is responsible for |

crane rating of this crane. | compliance with all applicable federal and |

state regulations. They are required to | |

Notice: | certify that the vehicle is in compliance with |

PTO and Pump installation instructions are | the Federal Motor Vehicle Safety Standards |

provided by the corresponding | and other regulations issued under the |

manufacturers. For more information on | National Traffic and Motor Vehicle Safety |

which PTO and Pump fit your application, | Act. |

please contact your local Stellar Distributor | |

or Stellar Customer Service. | Please reference the Code of Federal |

Regulations, title 49 - Transportation, Volume | |

Important: When installing welder units to the service | |

5 (400-999), for further information, or visit | |

bodies, it is highly recommended that a surge | |

http://www.gpoaccess.gov/nara/index.html | |

protector is installed on the chassis batteries to protect | |

the crane radio receiver, wiring and other electronic | for the full text of Code of Federal |

devices from an unexpected electrical spike or surge. | Regulations. |

Failure to do so could result in extensive damage to | |

the service body and crane electrical circuit. |

4EC3200 Owner’s Manual

Installation Overview

1.Determine that the mounting location for the EC3200 crane is at least 18” x 15” (45.7 x 38.1 cm).

2.Use the detail on the following page to drill .938” diameter holes into the mounting plate. Run tap on the threads of the base to be sure they are clean.

3.Use a crane or lifting device capable of lifting the weight of the Stellar crane. The Stellar EC3200 weighs approximately 800 lbs (360 kg). Note: cranes are shipped with rotation positioned at 180 degrees from normal stowed travel position. This will allow for easy installation of the crane and permanent connection of all hydraulic and electrical components prior to repositioning into the crane saddle.

4.Connect straps or chain from the lifting device to the main boom of the Stellar EC3200.

5.Use four (4) 7⁄8” x 1-3⁄4” #8 bolts and four (4) #8 7⁄8” flat washers.

6.Install a washer on each bolt.

7.Apply Loctite Thread locker #277 to the bolts.

8.Using the lifting device, lower the Stellar EC3200 just above the crane compartment and start the bolts. Have someone assist in leveling the crane.

9.Secure the crane using the mounting hardware provided. Note: longer or shorter cap screws may be required – recommended thread engagement into crane base is 0.75” – use grade 8, zinc plated cap screws only.

Hetronic Programming Manual Pdf

10.Torque the cap screws to 454 ft-lbs.

11.Remove supporting crane.

12.Hook-up hydraulics and electrical using the schematics provided at the end of this chapter.

Note: If questions should arise during any portion of this installation, please contact Stellar Customer Service at (800) 321-3741.

ck |

Tru |

of |

Front |

WARNING!

The use of this crane on a body not capable of handling the loads imposed on it may result in serious injury or death.

Installation 5

EC3200 Mounting Detail

Standard |

FRONT |

3.00 |

10.00 |

5.00 |

7.38 |

14.75 |

HOLE MOUNTING DETAIL |

FRONT | Narrow |

Base | |

14.75 | |

7.38 | |

5.00 | |

10.00 | |

HOLE MOUNTING DETAIL |

Flatbed Body Reinforcement

If it has been determined that the destination body won’t support the crane with a fully rated load, the body must be reinforced. Use 1/4” fillet welds and an ASWS qualified welder to proceed as shown in this drawing:

3/8 PLATE

TUBE 4X2X0.38

Note: Tubing must be at least 4” x 2” x 0.38” (Except where noted)

TUBE 2X2X0.38(TYP 4) TRUCK FRAME

TUBE 4X2X0.38

Every Hetronic control system is put together with the greatest possible care. We make each radio remote unit is custom made based on the wishes and requirements of our clients. However, sometimes intensive use leads to a repair or maintenance. And Hetronic is of course the place to be for that too.

We are Licensed Assembling Partner of Hetronic International. In our Service Center in Weesp (in the Netherlands), we carry out all repairs on Hetronic radio remote controls. If inspection we assess that the system is outdated and/or repair is no longer viable or possible, then we discuss this with you and together look for the best solution.

Hetronic’s bespoke repair service

We provide you with a bespoke repair service. Select the method of repair that fits you best, depending on how long you can miss your Hetronic system and whether or not you possess a reserve Hetronic control system. You just send us your radio remote control system, or pop in to our Service Center or have us carry out a repair on-site.

1. Just send it to us, fast and easy

Just send your radio remote control system and we’ll return your system repaired. Of course, if the repair is not covered by the warranty, we’ll first send you an estimate. Download the returns form and attach this to your repair request of your Hetronic.

2. Pop in, and we’ll fix it while you wait

Hetronic Programming Manual Software

Come along with your Hetronic control system for an appointment in Weesp.

3. At your location or on-site at your client’s

We carry out repairs at your location or on-site at your client’s. While you’re working, we will ensure you soon have a fully functioning radio remote control system again.

Hetronic b.v.

attn. Technical Services

Rijnkade 15

1382 GS Weesp

Netherlands

Contact

From the Netherlands: +31 (0)294 239 870

Hetronic Programming Manual Instruction

From Belgium: +32 (0)38 081 962

Per email: info@hetronic.nl

Repairs on-site

If your company is located in the Netherlands or Belgium, then we can repair your Hetronic radio remote control system on-site. Of course we do all this in consultation, and find a solution to your problem together with you. Maybe your company has changed and a different Hetronic system would be a better solution.

We will naturally supply a replacement system is necessary, so that your operations do not have to be stopped.

Hetronic Programming Manual Programming

Periodic maintenance

Hetronic Programming Manual Guide

Periodic maintenance prevents irregularities and extends the reliability and lifespan of your radio remote control system. In some branches and companies, preventive maintenance is even obligatory. We’d be delighted to carry out this maintenance for you, so you can enjoy the benefits of your Hetronic system for as long as possible.